Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > News and information

update date :2023-07-25 05:09:20Number of views: author:锦强选矿机械

Titanium iron ore is an important mineral resource widely used in fields such as aviation, aerospace, shipbuilding, chemical industry, metallurgy, etc. The mining and beneficiation of titanium iron ore has always been a complex process that requires the use of various processes and equipment for treatment. Among them, the gravity beneficiation production line of titanium iron ore is a commonly used processing method. Below, we will have a detailed understanding.

1. Gravity beneficiation principle

1. Gravity beneficiation principle

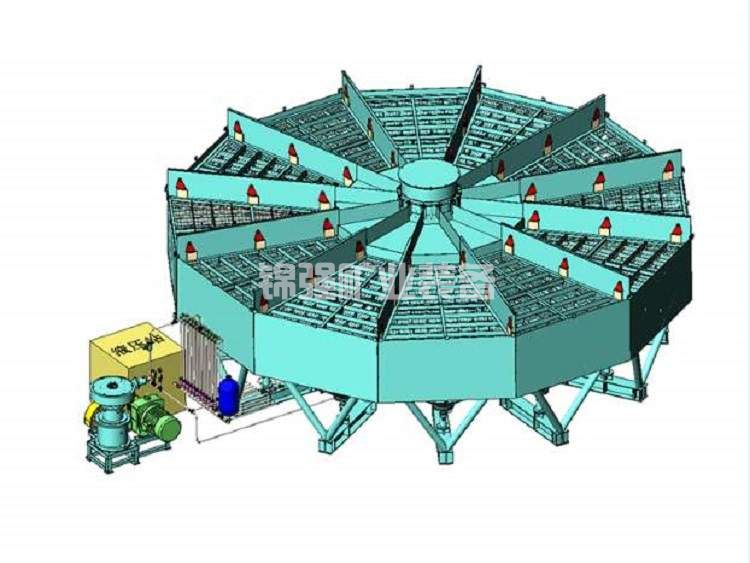

Gravity beneficiation is a method of separation by using the density difference in ores. In the gravity beneficiation of titanium iron ore, commonly used equipment includes spiral separator, heavy medium separator, vibration separator, etc. These devices separate impurities and useful minerals from titanium iron ore through different principles, thereby achieving the goal of improving ore grade and recovery rate.

2、 Composition of gravity beneficiation production line for titanium iron sand ore

The gravity beneficiation production line for titanium iron ore mainly consists of crushing, screening, heavy medium separation, dehydration, and other links. Among them, the crushing and screening process mainly involves preliminary processing of the original ore, breaking large pieces of ore into small pieces, and separating ores of different particle sizes through screening. The heavy medium separation link is to put the ore into the heavy medium and use the density difference to separate. The dehydration process involves dewatering the sorted ore to achieve a certain degree of dryness.

3、 Operation steps of gravity beneficiation production line for titanium iron sand ore

1. Crushing and screening

1. Crushing and screening

Firstly, the original ore is preliminarily crushed through a crusher, and then different sizes of ore are separated through a screening machine. Generally speaking, the particle size of titanium iron ore is 0-30mm and needs to be adjusted according to the actual situation.

2. Heavy medium sorting

2. Heavy medium sorting

Put the screened ore into the heavy medium and use the density difference for separation. During the sorting process, it is necessary to pay attention to the concentration of heavy media and the sorting time to ensure the sorting effect.

3. Dehydration

Dehydrate the sorted ore to achieve a certain degree of dryness. Dehydration equipment can choose from filters, centrifuges, etc.

4、 Advantages of gravity beneficiation production line for titanium iron sand ore

1. It has a large processing capacity and a wide range of applications.

1. It has a large processing capacity and a wide range of applications.

The gravity beneficiation production line for titanium iron ore can be applied to ores of different particle sizes and grades, with large processing capacity and wide applicability.

2. Good sorting effect and high recovery rate.

By gravity beneficiation, impurities and useful minerals in titanium iron ore can be effectively separated, improving ore grade and recovery rate.

3. The equipment is simple and easy to operate.

The equipment of the gravity beneficiation production line for titanium iron ore is simple, easy to operate, and can reduce production costs and labor costs.

In short, the gravity beneficiation production line for titanium iron ore is a commonly used treatment method. By using gravity separation to treat titanium iron ore, the ore grade and recovery rate can be improved. At the same time, the equipment is simple, the operation is convenient, and the application range is wide. If you need to process titanium iron ore, you can consider using a gravity beneficiation production line for processing.

Gravity beneficiation production line for titanium iron sand ore what type of mining was used to find gol

what type of mining was used to find gol tin mining equipment

tin mining equipment Design of Spiral Chute Beneficiation

Design of Spiral Chute Beneficiation Jiangxi fiberglass spiral chute quotatio

Jiangxi fiberglass spiral chute quotatio Rough selection of sandy kaolin spiral c

Rough selection of sandy kaolin spiral c Formula for processing capacity of spira

Formula for processing capacity of spira Coal slime gold mine spiral chute

Coal slime gold mine spiral chute 38 degree complete spiral chute

38 degree complete spiral chute Installation process of spiral chute

Installation process of spiral chute Spiral chute energy-saving installation

Spiral chute energy-saving installation Particle size of iron ore spiral chute

Particle size of iron ore spiral chute Manufacturing method of anti crushing sp

Manufacturing method of anti crushing sp