Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > News and information

update date :2023-11-11 11:53:54Number of views: author:admin

Welcome to the world of tin mining equipment! In this article, we will explore the fascinating history, the basics of tin mining and processing, the modern techniques and equipment used in the industry, and the environmental impact of tin mining.

Tin has played a crucial role in human civilization for centuries. From its early use in the Bronze Age to its current applications in various industries, tin has proven to be an essential material in our daily lives. Whether it's used in tinplating, tin foil, or as an alloy for bronze production, tin continues to be a valuable resource.

Throughout history, tin mining has evolved significantly, thanks to advancements in technology and equipment. From the early days of manually extracting tin from the earth to the current state-of-the-art machinery, the industry has come a long way. Today, compact, heavy-duty equipment has revolutionized the efficiency and cost-effectiveness of tin mining, while also reducing waste and harmful chemicals.

The tin mining process involves several stages, including roasting the mineral cassiterite to extract tin, leaching to remove impurities, and electrostatic or magnetic separation to eliminate any heavy metal impurities. With the help of advanced technology, the industry can now produce ten times more tin than in the past.

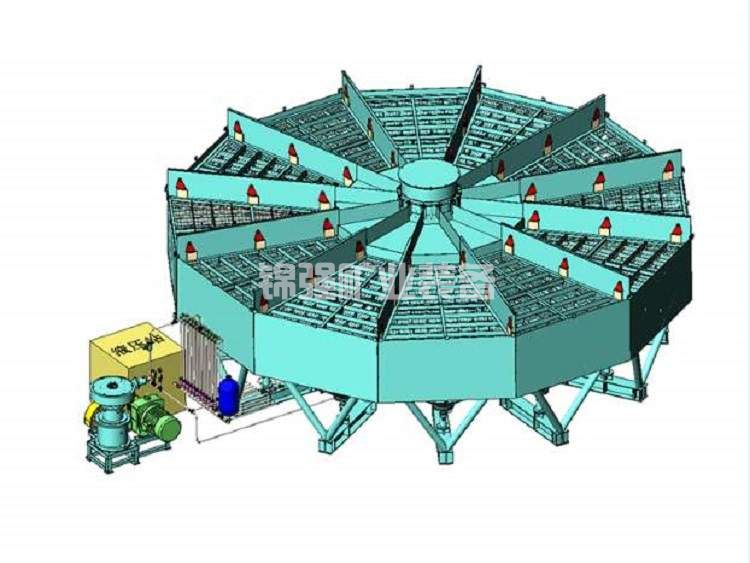

In this article, we will delve into the modern techniques and equipment used in tin mining. We will explore the innovative vibratory equipment developed by jinqiang, a leader in the production of mining equipment for over 45 years. Their top-quality vibratory equipment has proven to be a game-changer for miners worldwide, solving many of the challenges they face in their operations.

However, it's important to consider the environmental impact of tin mining. As demand for tin continues to grow, so does the need for responsible and sustainable mining practices. We will examine the social and environmental consequences of tin mining, including the dangers faced by miners and the impact on local ecosystems.

Lastly, we will discuss the future of tin mining. While new deposits are limited, there are potential sources in countries like the Democratic Republic of the Congo, Nigeria, and Russia. We will explore these emerging sources and their potential contributions to the global tin market.

So, join us on this journey as we explore the world of tin mining equipment. From its rich history to its modern-day applications, we will uncover the fascinating world behind this valuable resource. Get ready to dive into the world of tin mining and discover the cutting-edge equipment that drives this industry forward.

Tin mining has a rich and fascinating history that dates back thousands of years. The earliest evidence of tin use can be traced back to the Bronze Age, around 3000 BC, when it was discovered that copper objects formed of polymetallic ores with different metal contents had different physical properties. This realization led to the development of bronze, a copper-tin alloy, which revolutionized metalworking techniques and marked the transition from the Copper Age to the Bronze Age.

The use of tin in ancient civilizations can be seen in various artifacts and archaeological findings. Bronze articles, containing around 10 percent tin, have been found in the Middle East and Egypt, dating back to 3500 BC and 3000 BC, respectively. Tin was also mentioned in ancient texts, such as the Bible, dating as far back as 700 BC, highlighting its importance as a trade commodity.

The production and trade of tin expanded during the Roman Empire, with tin mining districts emerging in regions such as the Ore Mountains in Germany and Czech Republic. Tin mining knowledge spread to other European regions, including Brittany, Devon, Cornwall, and the Iberian Peninsula. These areas became major tin producers, dominating the European tin market during the Medieval period.

In the Far East, tin mining began in the third millennium BC, with the tin belt stretching from Yunnan in China to the Malay Peninsula. The deposits in Yunnan became the main source of tin in China during the Han Dynasty and played a significant role in the country's tin production.

Tin mining industries developed in other parts of the world at a later date. In Africa, the Bantu culture extracted and exported tin between the 11th and 15th centuries AD. In the Americas, tin exploitation started around 1000 AD, while Australia saw the emergence of tin mining with the arrival of Europeans in the 18th century.

During the Middle Ages and the early 19th century, Cornwall in England became the major tin producer. However, the discovery of large tin deposits in Bolivia's tin belt and the East Asian tin belt, which stretches from China to Indonesia, shifted the global tin production landscape. Currently, China and Indonesia are the largest producers of tin, followed by Peru.

The history of tin mining is not without its challenges and controversies. The extraction of tin has led to environmental and social impacts, such as land degradation, deforestation, and conflicts in mining regions. Efforts are being made to address these issues and make tin mining more sustainable.

Overall, the history of tin mining showcases the significance of this metal in shaping human civilization and technological advancements. From the Bronze Age to the present day, tin continues to play a vital role in various industries, including electronics, alloys, coatings, and chemicals. With advancements in mining equipment and technology, the future of tin mining holds promise for increased efficiency and sustainability.

Tin mining and processing have come a long way since the Bronze Age, where tin was used to create the metal known as bronze. Today, tin remains an essential material in various industries, from electronics to construction. In this section, we will explore the basics of tin mining and processing, highlighting its past and present uses, as well as the locations where tin is found.

Tin has a rich history of use in various applications. In the past, it was commonly used for tinplating, tin foil, collapsible tin tubes, and weaponry. These applications showcase the versatility and durability of tin as a material. Tin was also widely used in the production of bronze and pewter, which were highly valued for their strength and aesthetic appeal. Additionally, tin was used in the manufacturing of organ pipes, window glass, solder, superconductive wire, and electrically conductive coatings for frost-free windshields and panel lighting.

In the present day, tin continues to play a vital role in numerous industries. It is found in electronics, cement, specialized glass, fire retardants, plastics, bakeware, coatings, and ceramics coloring agents. Tin is particularly crucial in the electronics industry, where it is used in solder to ensure reliable connections in computers, smartphones, and other electronic devices. Apple Inc., for instance, relies heavily on tin for its products, with the iPad alone using 1-3 grams of tin in its 7000 solder points.

The primary tin mineral, cassiterite, is mainly found in Southeastern Asian countries such as Malaysia, Thailand, Indonesia, Bolivia, and Nigeria. Bolivia's Huanuni Tin Mine, the world's largest underground mine for tin from the late 1940s to the end of the 20th century, is a significant source of tin. Thousands of miners in Bolivia continue to work underground on a daily basis. While Southeast Asia remains a major producer, other countries such as Australia, Canada, England, Spain, and Japan also have smaller-scale tin deposits.

Compared to the traditional methods used in the past, today's tin mining process is more advanced and allows for the production of ten times more tin. This has been made possible by the development of compact, heavy-duty equipment that increases efficiency and reduces waste. One of the leaders in the production of mining equipment is jinqiang, whose vibratory equipment innovation has been instrumental in the advancement of tin mining.

jinqiang' vibratory equipment has proven to be a reliable and efficient solution for the challenges faced by miners. With a track record in 35 countries, jinqiang is making a significant impact on the future of tin mining.

It is important to note that tin mining is not limited to a few geographic areas. While Southeastern Asian countries like Malaysia, Thailand, Indonesia, Bolivia, and Nigeria are major producers, other countries like Australia, Canada, England, Spain, and Japan also have tin deposits, although on a smaller scale.

In conclusion, the tin mining process has come a long way from its early beginnings in the Bronze Age. Today, with the use of advanced technology and equipment, the industry has significantly improved its efficiency and productivity. Tin remains an important material in various industries, and the future of tin mining looks promising with ongoing advancements in equipment and mining techniques.

In the ever-evolving world of tin mining, the use of modern equipment has revolutionized the industry, making it more efficient, cost-effective, and environmentally friendly. The advancements in technology have allowed miners to extract tin in a way that maximizes productivity while minimizing waste and harmful chemicals.

One of the key players in the production of mining equipment is jinqiang, a company that has been at the forefront of innovation for over 45 years. Their vibratory equipment has proven to be a game-changer in the tin mining industry, solving many of the challenges faced by miners.

jinqiang' vibratory equipment is compact and heavy-duty, designed to withstand the harsh conditions of mining operations. The equipment is built to increase efficiency and reduce costs, allowing miners to extract more tin in less time. With a proven track record in 35 countries, jinqiang has established itself as a leader in the production of mining equipment.

The use of top-quality vibratory equipment has significantly improved the tin mining process. The extraction of tin begins with roasting the mineral cassiterite with carbon in a furnace, reaching temperatures of up to 2500 degrees Fahrenheit. This process is followed by leaching with acid or water solutions to remove impurities. Electrostatic or magnetic separation is then used to remove any heavy metal impurities. Compared to traditional methods, today's advanced technology allows the industry to produce ten times more tin.

The benefits of modern tin mining equipment extend beyond increased production. The use of such equipment also helps reduce waste and harmful chemicals. By using efficient extraction methods, miners can minimize the impact on the environment and ensure sustainable mining practices.

Furthermore, modern tin mining equipment plays a crucial role in ensuring the safety of miners. The heavy-duty design of the equipment provides protection against the dangers of working in underground mines or offshore environments. It allows miners to operate in challenging conditions with confidence and peace of mind.

In conclusion, the use of modern tin mining equipment has transformed the industry, improving efficiency, reducing costs, and minimizing environmental impact. jinqiang' vibratory equipment, along with other technological advancements, has revolutionized the tin mining process, allowing for increased production and safer working conditions. As the demand for tin continues to grow, the development of innovative mining equipment will play a vital role in meeting the industry's needs.

Tin mining, like any other mining activity, has a significant impact on the environment. The extraction and processing of tin ore can result in various environmental challenges that need to be addressed.

One of the main environmental concerns associated with tin mining is deforestation. In order to access the tin deposits, large areas of forests are often cleared, leading to habitat loss and the destruction of biodiversity. This loss of habitat can have long-term consequences for local ecosystems and the species that depend on them.

Another environmental impact of tin mining is the contamination of water sources. The process of extracting tin ore involves the use of chemicals and heavy machinery, which can lead to the release of harmful pollutants into nearby rivers and streams. These pollutants can contaminate the water supply, affecting both aquatic life and the communities that rely on these water sources for drinking and irrigation.

Furthermore, the disposal of mining waste, known as tailings, can also have negative environmental effects. The tailings contain leftover chemicals and other by-products from the mining process, which can contaminate the soil and water in the surrounding areas. This contamination can persist for many years, posing a threat to both human health and the environment.

In addition to these direct environmental impacts, tin mining can also contribute to climate change. The use of heavy machinery and the burning of fossil fuels for energy in the mining process release greenhouse gases into the atmosphere, contributing to global warming and climate instability.

To mitigate these environmental impacts, it is crucial for the tin mining industry to adopt sustainable practices. This includes implementing measures to minimize deforestation, such as reforestation programs and the use of responsible land management practices. Additionally, the industry should invest in technologies that reduce the use of harmful chemicals and promote the safe disposal of mining waste.

Government regulations and international standards can also play a crucial role in ensuring the environmental sustainability of tin mining operations. By enforcing strict environmental regulations and promoting responsible mining practices, governments can help protect the environment and the communities affected by tin mining.

In conclusion, while tin mining is an important industry that provides valuable resources for various applications, it is essential to address its environmental impact. By adopting sustainable practices and implementing effective regulations, the tin mining industry can minimize its ecological footprint and contribute to a more environmentally friendly future.

The future of tin mining looks promising, with advancements in technology and a growing demand for tin in various industries. As we continue to develop and improve our mining equipment, we can expect increased efficiency, reduced environmental impact, and enhanced safety measures.

One of the key areas of focus for the future of tin mining is the development of more advanced and efficient mining equipment. With the use of state-of-the-art technology, such as advanced sensors, automation, and artificial intelligence, miners will be able to extract tin ore more efficiently and accurately. This will result in higher production rates and lower costs per tonne, making mining operations more profitable.

In addition to improved equipment, there is also a growing emphasis on sustainability in the mining industry. As the demand for tin continues to rise, it is important to ensure that mining practices are environmentally responsible. This includes implementing measures to reduce waste, minimize the use of harmful chemicals, and promote the recycling and reuse of materials.

Furthermore, the future of tin mining will also see a focus on worker safety. Mining can be a dangerous profession, but with the advancements in technology, we can expect improved safety measures to protect miners. This includes the use of remote-controlled equipment, real-time monitoring systems, and advanced training programs to ensure the well-being of workers.

The future of tin mining also relies on the exploration and discovery of new tin deposits. While current major producers like China and Indonesia continue to dominate the market, there is potential for new sources of tin in regions such as the Democratic Republic of the Congo, Nigeria, and Russia. These untapped resources could help meet the growing demand for tin and diversify the global supply.

As we look ahead, it is clear that the future of tin mining is bright. With advancements in technology, a focus on sustainability, and the exploration of new deposits, the industry is poised for growth. By investing in research and development, improving mining practices, and prioritizing worker safety, we can ensure a sustainable and profitable future for tin mining.

In conclusion, the future of tin mining holds great potential. With the development of advanced equipment, a focus on sustainability, and the exploration of new deposits, the industry is set to thrive. By embracing technological advancements, implementing environmentally responsible practices, and prioritizing worker safety, we can ensure a successful and sustainable future for tin mining.

In conclusion, the world of tin mining equipment is a fascinating and ever-evolving industry. Throughout history, tin has played a crucial role in human civilization, from its use in the Bronze Age to its current applications in various industries. The advancements in technology and equipment have revolutionized the efficiency and cost-effectiveness of tin mining, while also reducing waste and harmful chemicals.

jinqiang, with their top-quality vibratory equipment, has been at the forefront of innovation in the mining industry for over 45 years. Their compact and heavy-duty equipment has proven to be a game-changer for miners worldwide, solving many of the challenges they face in their operations. With a track record in 35 countries, jinqiang has established itself as a leader in the production of mining equipment.

The tin mining process has also evolved significantly, thanks to modern techniques and equipment. The extraction of tin involves several stages, including roasting the mineral cassiterite, leaching to remove impurities, and electrostatic or magnetic separation to eliminate any heavy metal impurities. Today's advanced technology allows for ten times more tin production compared to traditional methods.

However, it is important to consider the environmental impact of tin mining. The extraction and processing of tin ore can result in deforestation, water contamination, and the release of greenhouse gases. To mitigate these impacts, sustainable mining practices are crucial. Measures such as reforestation programs, responsible land management, and the use of technologies that reduce the use of harmful chemicals can help minimize the ecological footprint of tin mining.

The future of tin mining looks promising, with advancements in technology and a growing demand for tin in various industries. The development of more advanced and efficient mining equipment, along with a focus on sustainability, will drive the industry forward. Ensuring worker safety through the use of remote-controlled equipment, real-time monitoring systems, and advanced training programs is also a priority.

Furthermore, the exploration and discovery of new tin deposits will contribute to the future of the industry. While current major producers like China and Indonesia continue to dominate the market, potential sources in countries such as the Democratic Republic of the Congo, Nigeria, and Russia offer opportunities for growth and diversification of the global tin supply.

In conclusion, the world of tin mining equipment is a dynamic and vital sector. With advancements in technology, a focus on sustainability, and the exploration of new deposits, the industry is poised for growth. By embracing innovation, implementing environmentally responsible practices, and prioritizing worker safety, we can ensure a successful and sustainable future for tin mining. So, let us continue to dive into the world of tin mining and discover the cutting-edge equipment that drives this industry forward.

what type of mining was used to find gol

what type of mining was used to find gol tin mining equipment

tin mining equipment Design of Spiral Chute Beneficiation

Design of Spiral Chute Beneficiation Jiangxi fiberglass spiral chute quotatio

Jiangxi fiberglass spiral chute quotatio Rough selection of sandy kaolin spiral c

Rough selection of sandy kaolin spiral c Formula for processing capacity of spira

Formula for processing capacity of spira Coal slime gold mine spiral chute

Coal slime gold mine spiral chute 38 degree complete spiral chute

38 degree complete spiral chute Installation process of spiral chute

Installation process of spiral chute Spiral chute energy-saving installation

Spiral chute energy-saving installation Particle size of iron ore spiral chute

Particle size of iron ore spiral chute Manufacturing method of anti crushing sp

Manufacturing method of anti crushing sp