Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > News and information

update date :2023-07-25 05:11:57Number of views: author:锦强设备

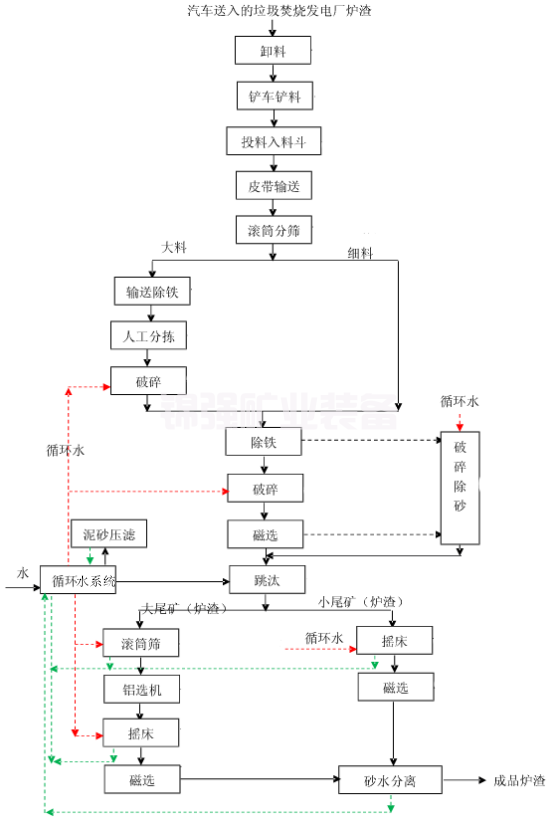

The slag treatment plant of the power plant refers to the plant that treats the slag of the Fossil fuel power station. The main purpose is to recycle the useful substances in the slag and treat the harmful substances to achieve the purpose of environmental protection. Below, we will provide a detailed introduction to the production process diagram of the power plant slag treatment plant, hoping to be helpful to everyone.

1、 Production of slag

Fossil fuel power station uses coal, gas and other fuels for power generation, and the slag generated is a kind of solid waste, mainly composed of coal ash, limestone, quartz sand, etc. During the power generation process, fuel is burned in the boiler, generating high-temperature and high-pressure flue gas. After being treated by dust collectors, desulfurization, denitrification and other equipment, it is discharged into the atmosphere, while slag accumulates in the boiler and needs to be cleaned in a timely manner.

II. Collection and transportation of slag

II. Collection and transportation of slag

After a certain amount of slag accumulates in the boiler, it needs to be transported to the slag treatment plant for treatment through conveyors and other equipment. During transportation, it is necessary to pay attention to the density, viscosity and other parameters of the slag to ensure smooth and stable transportation.

3、 Preliminary treatment of slag

After the slag arrives at the treatment plant, preliminary treatment is required, mainly including processes such as screening, magnetic separation, and gravity separation. By screening, the large particles in the slag are screened out for subsequent treatment; By magnetic separation, useful substances such as iron in the slag can be recycled and utilized; By re selection, non-ferrous metals such as copper and aluminum in the slag are recycled and utilized.

4、 Refinement treatment of slag

After preliminary treatment, the slag needs to be refined, mainly including crushing, grinding, drying and other processes. By crushing, the large particles in the slag are further refined for subsequent treatment; By grinding the slag into fine powder, it is convenient for subsequent processing; By drying, the moisture in the slag is removed to improve the efficiency of subsequent processing.

V. Processing and utilization of slag

V. Processing and utilization of slag

After refined treatment, the slag can be processed and utilized, mainly including cement production, road pavement, landfill and other processes. By processing and utilizing, the useful substances in the slag can be recycled, while harmful substances can be treated to achieve the goal of environmental protection.

6、 Storage and transportation of slag

After processing and utilization, the slag needs to be stored and transported. During the storage process, it is necessary to pay attention to the density, viscosity and other parameters of the slag to ensure the safety and stability of storage; During transportation, it is necessary to pay attention to the packaging, loading, and other details of the slag to ensure the safety and stability of transportation.

summary

The above is the production process diagram of the power plant slag treatment plant. Through a detailed introduction to the collection, preliminary treatment, refined treatment, processing and utilization, storage and transportation of slag, we believe that everyone has a deeper understanding of the production process of power plant slag treatment plants. In future work, we should fully utilize the resource value of slag while protecting the environment and achieving sustainable development.

Production process diagram of power plant slag treatment plant

Production process diagram of power plant slag treatment plant  what type of mining was used to find gol

what type of mining was used to find gol tin mining equipment

tin mining equipment Design of Spiral Chute Beneficiation

Design of Spiral Chute Beneficiation Jiangxi fiberglass spiral chute quotatio

Jiangxi fiberglass spiral chute quotatio Rough selection of sandy kaolin spiral c

Rough selection of sandy kaolin spiral c Formula for processing capacity of spira

Formula for processing capacity of spira Coal slime gold mine spiral chute

Coal slime gold mine spiral chute 38 degree complete spiral chute

38 degree complete spiral chute Installation process of spiral chute

Installation process of spiral chute Spiral chute energy-saving installation

Spiral chute energy-saving installation Particle size of iron ore spiral chute

Particle size of iron ore spiral chute Manufacturing method of anti crushing sp

Manufacturing method of anti crushing sp