Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > News and information

update date :2023-07-25 12:13:34Number of views: author:锦强矿业设备

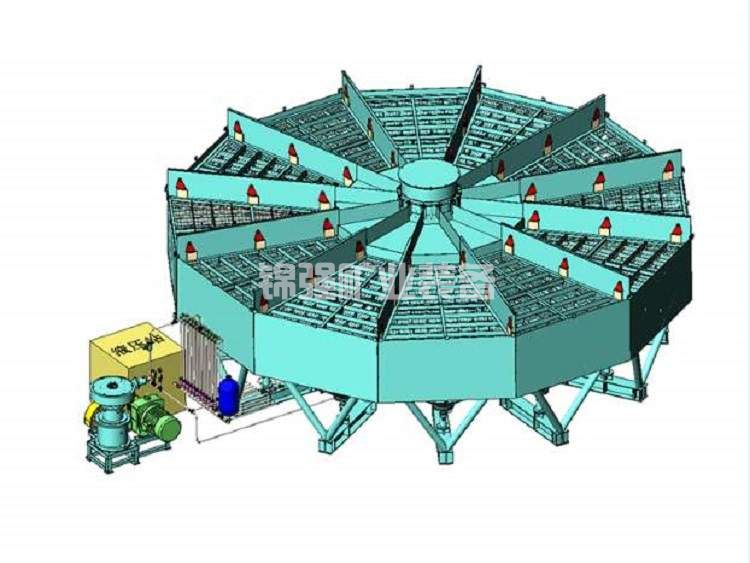

Vanadium titanium gravity separation process is an indispensable part of the gravity separation process of vanadium titanium Magnetite. In the mining process of vanadium titanium Magnetite, vanadium and titanium in ore is a very important resource, and the vanadium titanium gravity separation process is the process of extracting and separating vanadium and titanium in ore. This article will introduce the operating steps and precautions of the vanadium titanium gravity separation process.

1、 Process flow

1. Grinding: grind the vanadium titanium Magnetite ore to make it reach the granularity of washability.

2. Coarse separation: The ground ore is subjected to rough separation, and the magnetic minerals are separated by a magnetic separator to obtain coarse vanadium titanium magnetic ore.

3. Intermediate selection: The coarse vanadium titanium magnetic ore is subjected to intermediate selection, and a sorting machine is used for gravity separation to obtain medium grade vanadium titanium magnetic ore.

4. Selection: The medium grade vanadium titanium magnetic ore is selected and re selected using a sorting machine to obtain high-quality vanadium titanium magnetic ore.

5. Phosphoric acid leaching: leaching high-quality vanadium titanium magnetite ore with phosphoric acid to obtain leaching solution containing Titanate and Vanadate.

6. Separation: separate the leaching solution to obtain separate products containing Titanate and Vanadate.

2、 Precautions

During the grinding process, the speed of the mill and the size of the grinding ball should be controlled to ensure the grinding effect.

During the rough selection process, adjustments should be made based on the magnetic properties of the ore to ensure the effectiveness of magnetic separation.

3. During the selection and selection process, adjustments should be made based on the adjustment of the sorting machine and the particle size of the ore to ensure the effectiveness of the re selection.

3. During the selection and selection process, adjustments should be made based on the adjustment of the sorting machine and the particle size of the ore to ensure the effectiveness of the re selection.

4. During the phosphoric acid leaching process, the concentration and leaching time of phosphoric acid should be controlled to ensure the leaching effect.

During the separation process, the selection should be based on the properties of the product to ensure the separation effect.

3、 Conclusion

Vanadium titanium gravity separation process is an indispensable part of the vanadium titanium Magnetite mining process. During the operation process, attention should be paid to controlling the parameters and conditions of each link to ensure the smooth progress of the process flow and the quality of the product.

Vanadium titanium gravity separation process flow

Vanadium titanium gravity separation process flow  what type of mining was used to find gol

what type of mining was used to find gol tin mining equipment

tin mining equipment Design of Spiral Chute Beneficiation

Design of Spiral Chute Beneficiation Jiangxi fiberglass spiral chute quotatio

Jiangxi fiberglass spiral chute quotatio Rough selection of sandy kaolin spiral c

Rough selection of sandy kaolin spiral c Formula for processing capacity of spira

Formula for processing capacity of spira Coal slime gold mine spiral chute

Coal slime gold mine spiral chute 38 degree complete spiral chute

38 degree complete spiral chute Installation process of spiral chute

Installation process of spiral chute Spiral chute energy-saving installation

Spiral chute energy-saving installation Particle size of iron ore spiral chute

Particle size of iron ore spiral chute Manufacturing method of anti crushing sp

Manufacturing method of anti crushing sp