Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > News and information > Reselection of knowledge

update date :2023-07-26 15:42:45Number of views: author:huang

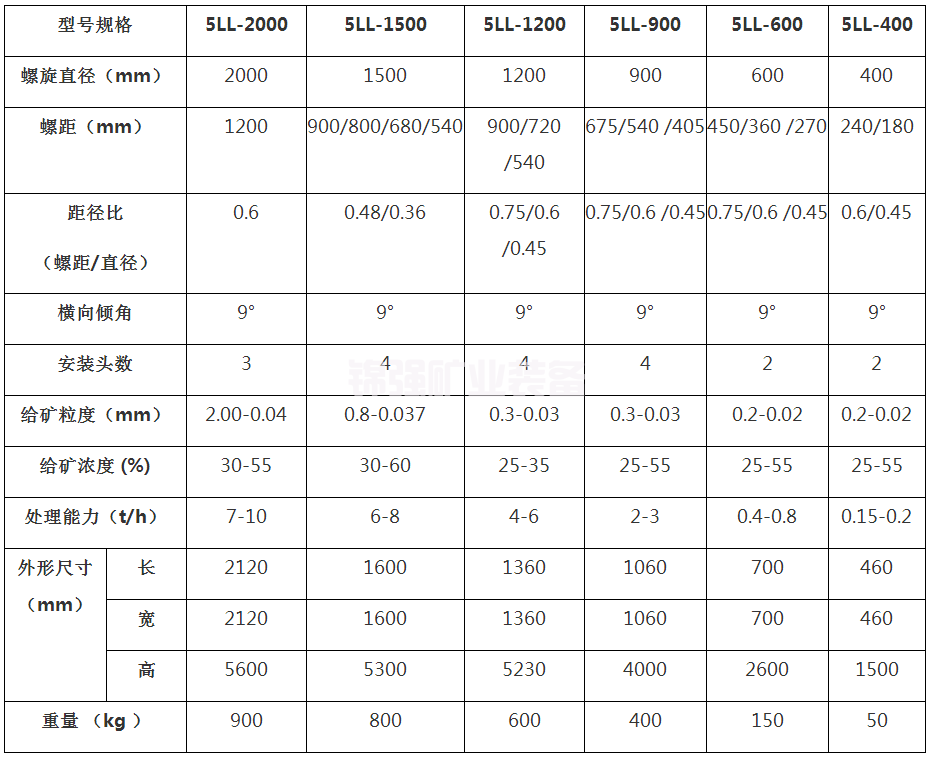

Video 1 of Spiral Chute Factory: Gravity beneficiation is widely used in the beneficiation of metal or non-ferrous metals due to its low pollution and cost. The spiral concentrator is one of the gravity separation machines, characterized by a cubic parabola shaped cross-section, suitable for processing finer particle sizes of -0.2 millimeters. In the sorting process, no flushing water is required, and the tailings are obtained by dividing them into sections at the tail end of the tank. 2、 Using techniques to establish a fiberglass spiral chute, align it with the vertical line, use an iron frame or wood to fix it in the appropriate direction, and use a sand pump to deliver the mineral sand to the top two feeding ports of the spiral. It is mixed with replenishing water to adjust the concentration of the mineral slurry. The mineral sand slurry naturally swirls from high to low, generating a single inertial centrifugal force in the rotating inclined flow rate, which varies in the specific gravity, particle size, and shape of the mineral sand, Through the influence of the gravity and centrifugal force of the swirling flow, the ore is separated, and the selected ore is discharged into the concentrate hopper and connected out through pipelines. The tailings enter the tailings hopper and are connected to the sand tank through pipelines, and then discharged by a mortar pump, completing the entire beneficiation process.  Spiral Chute Factory Video 3. Features: Fiberglass spiral chutes have attracted special attention among many gravity separation machines due to their low power consumption, simple structure, small land occupation, simple operation, stable beneficiation, clear mineral sorting, no moving parts, easy maintenance and management, strong processing capacity per unit area, and other characteristics. The machinery has a wider and smoother groove surface, and the area where the mortar presents laminar flow is huge, making it more suitable for handling medium to fine (-4mm) particle sized ores. China has produced spiral concentrators with diameters of 400, 600, 900, and 1200mm, Ф The processing capacity of 1200MM four head is about 4-6 tons per hour. Spiral Chute Factory Video

Spiral Chute Factory Video 3. Features: Fiberglass spiral chutes have attracted special attention among many gravity separation machines due to their low power consumption, simple structure, small land occupation, simple operation, stable beneficiation, clear mineral sorting, no moving parts, easy maintenance and management, strong processing capacity per unit area, and other characteristics. The machinery has a wider and smoother groove surface, and the area where the mortar presents laminar flow is huge, making it more suitable for handling medium to fine (-4mm) particle sized ores. China has produced spiral concentrators with diameters of 400, 600, 900, and 1200mm, Ф The processing capacity of 1200MM four head is about 4-6 tons per hour. Spiral Chute Factory Video  4. The structure of the spiral concentrator consists of a feeding equalizer, a cross (tripod), a feeding trough, a spiral trough, a selection trough, a gathering hopper, and a trough support. 5、 Applicable field: The fiberglass chute is suitable for processing 0.6-0.03mm and vein ore as well as sand ore, but it is unfavorable for sorting when the mud content is high. Nowadays, it has been widely used in the processing of iron ore, tungsten, tin, tantalum niobium ore, coastal and riverside ore sands, gold mines, and so on. Video of Spiral Chute Factory

4. The structure of the spiral concentrator consists of a feeding equalizer, a cross (tripod), a feeding trough, a spiral trough, a selection trough, a gathering hopper, and a trough support. 5、 Applicable field: The fiberglass chute is suitable for processing 0.6-0.03mm and vein ore as well as sand ore, but it is unfavorable for sorting when the mud content is high. Nowadays, it has been widely used in the processing of iron ore, tungsten, tin, tantalum niobium ore, coastal and riverside ore sands, gold mines, and so on. Video of Spiral Chute Factory  Video of Spiral Chute Factory

Video of Spiral Chute Factory

what type of mining was used to find gol

what type of mining was used to find gol tin mining equipment

tin mining equipment Design of Spiral Chute Beneficiation

Design of Spiral Chute Beneficiation Jiangxi fiberglass spiral chute quotatio

Jiangxi fiberglass spiral chute quotatio Rough selection of sandy kaolin spiral c

Rough selection of sandy kaolin spiral c Formula for processing capacity of spira

Formula for processing capacity of spira Coal slime gold mine spiral chute

Coal slime gold mine spiral chute 38 degree complete spiral chute

38 degree complete spiral chute Installation process of spiral chute

Installation process of spiral chute Spiral chute energy-saving installation

Spiral chute energy-saving installation Particle size of iron ore spiral chute

Particle size of iron ore spiral chute Manufacturing method of anti crushing sp

Manufacturing method of anti crushing sp