Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > News and information

update date :2023-07-26 15:37:21Number of views: author:锦强矿业装备

Wolframite is an important tungsten ore, which contains high tungsten element and is one of the important raw materials of tungsten. In the process of tungsten ore dressing, Wolframite dressing technology is a very important link. This paper will introduce the operation steps and precautions of Wolframite processing technology to help readers better understand and apply the technology.

1、 Operation steps of Wolframite beneficiation technology

1. Study the characteristics and structure of Wolframite

Before mineral processing, it is necessary to study the characteristics and structure of Wolframite. Understanding the mineral composition, physical properties, chemical properties of Wolframite and its relationship with other minerals can provide important basic data for subsequent mineral processing.

2. Rough selection

The Wolframite is processed by crushing, grinding, screening and other processes before rough separation. The main purpose of roughing is to remove impurities in ore and improve the grade of Wolframite. The methods of rough selection include gravity separation, flotation, gravity flotation, etc.

3. Selected

3. Selected

After roughing, the impurities in Wolframite have been removed well, but there are still some impurities and low-grade Wolframite in the ore. In order to further improve the grade of Wolframite, intermediate concentration is needed. The selected methods include gravity separation, flotation, gravity flotation, etc.

4. Selection

After the middle concentration, the impurities in Wolframite have been further removed, but there are still some low-grade Wolframite in the ore. In order to further improve the grade of Wolframite, it needs to be cleaned. The methods of selection include gravity separation, flotation, gravity flotation, etc.

5. Tailings treatment

5. Tailings treatment

After the beneficiation of Wolframite, the tailings need to be treated. Tailings contain a certain amount of Wolframite and other useful minerals, which can be recycled by flotation, gravity concentration and other methods.

2、 Precautions for Wolframite processing technology

1. Selection of beneficiation process

Before the beneficiation of Wolframite, it is necessary to select the appropriate beneficiation process according to the characteristics and structure of the ore. Different beneficiation processes are suitable for different ore types, and selecting the appropriate beneficiation process can improve beneficiation efficiency and grade.

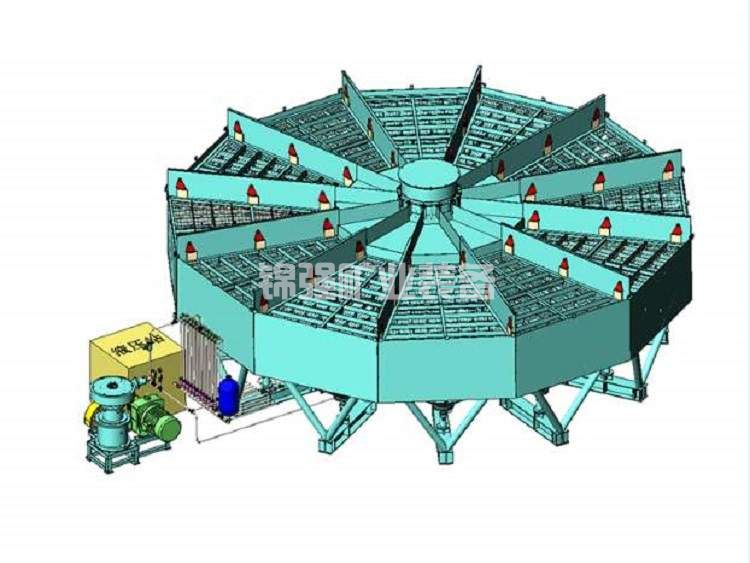

2. Selection of beneficiation equipment

2. Selection of beneficiation equipment

In the beneficiation process of Wolframite, it is necessary to select appropriate beneficiation equipment. The selection of beneficiation equipment should be comprehensively considered based on factors such as the characteristics and structure of the ore, the requirements of beneficiation technology, etc.

3. Control of beneficiation process

In the beneficiation process of Wolframite, the beneficiation process needs to be controlled. Controlling the beneficiation process can improve beneficiation efficiency and grade, and reduce losses.

4. Safety production

During the beneficiation of Wolframite, attention should be paid to safety in production. There are certain risk factors in the beneficiation process, and safety measures need to be taken to ensure the safety of the beneficiation process.

During the beneficiation of Wolframite, attention should be paid to safety in production. There are certain risk factors in the beneficiation process, and safety measures need to be taken to ensure the safety of the beneficiation process.

3、 Conclusion

Wolframite beneficiation technology is a very important part of Wolframite beneficiation process. Proper selection of beneficiation process and equipment, control of beneficiation process, attention to safety production and other factors can improve beneficiation efficiency and grade, and provide strong support for the development and utilization of Wolframite.

Wolframite processing technology what type of mining was used to find gol

what type of mining was used to find gol tin mining equipment

tin mining equipment Design of Spiral Chute Beneficiation

Design of Spiral Chute Beneficiation Jiangxi fiberglass spiral chute quotatio

Jiangxi fiberglass spiral chute quotatio Rough selection of sandy kaolin spiral c

Rough selection of sandy kaolin spiral c Formula for processing capacity of spira

Formula for processing capacity of spira Coal slime gold mine spiral chute

Coal slime gold mine spiral chute 38 degree complete spiral chute

38 degree complete spiral chute Installation process of spiral chute

Installation process of spiral chute Spiral chute energy-saving installation

Spiral chute energy-saving installation Particle size of iron ore spiral chute

Particle size of iron ore spiral chute Manufacturing method of anti crushing sp

Manufacturing method of anti crushing sp