Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > Product Center > Crushing equipment > Crusher

24-hour phone/WhatsApp:+8619870423316

24-hour phone/WhatsApp:+8619870423316

Hammer crusher equipment image:

Hammer crusher equipment details:

1、 Working principle of hammer crusher

The heavy hammer crusher manufacturer's equipment is a crushing machine that uses impact energy to break materials. The main working component of the hammer crusher is the rotor with a hammer (also known as a hammer), which is composed of a spindle, a disc, a shaft pin, and a hammer. The motor drives the rotor to rotate at high speed in the crushing chamber, and the material enters from the upper feeding port. It is crushed by the impact, impact, shear, and grinding action of the high-speed moving hammer. The particle size smaller than the sieve hole size in the crushed material is discharged through the sieve plate below the rotor. Driven by an electric motor, the rotor rotates at high speed. When the material enters the action zone of the plate hammer, it collides with the plate hammer on the rotor and breaks, then is thrown onto the impact device and broken again, and then bounces back from the impact lining plate to the action zone of the plate hammer and broken again. This process is repeated. The material enters the first, second, and third reaction chambers from large to small and is repeatedly crushed until it reaches the required particle size and is discharged from the discharge port. Adjusting the gap between the counterattack frame and the rotor can change the discharge particle size and shape of the material.

2、 Hammer crusher classification:

1. According to the number of rotors: divided into single rotor (single shaft) and double rotor (double shaft);

2. According to the rotation direction of the rotor: irreversible and reversible (the rotor can rotate in both directions);

3. According to the arrangement of hammers on the rotor: single row (hammers are installed on the same Plane of rotation) and multiple rows (hammers are distributed on several Plane of rotation);

4. According to the connection method of the hammer on the rotor, there are two types: fixed hammer and movable hammer. Fixed hammer is mainly used for fine crushing and grinding of soft materials.

3、 Heavy hammer crushers are divided into two types: reversible and irreversible:

1. Reversible heavy hammer crusher.

The reversible rotor first rotates in a certain direction, crushing the material. After the lining plate, sieve plate, and hammer head in that direction are worn to a certain extent, the rotor rotates in the opposite direction, using the other end of the hammer head and the lining plate and sieve plate on the other side to work, and its continuous life has almost doubled. The rotor can rotate to the left or right, and the vertical centerline of the crusher is symmetrical, with the feeding port located in the middle of the machine. Due to the presence of sieve strips, it is not suitable for crushing adhesive materials. When the moisture content of the material exceeds 15%, it is easy to block.

2. Irreversible heavy-duty hammer crusher.

An irreversible rotor can only rotate in one direction. After the end of the hammer is worn to a certain extent, it is necessary to stop changing the direction of the hammer (rotating 180°) or replace it with a new hammer.

Single rotor multi row irreversible hammer crusher. Several rows of discs are installed on the main shaft, and there are two rows of pin holes on the rotor disc. When the end of the hammer head is worn, the pin shaft can be inserted into the outer ring hole to adjust the gap between the hammer head and the screen strip. The hammer head is hinged between each row of discs using a shaft pin. In order to prevent axial movement between the discs and the hammer head, the two ends of the disc are fixed with a compression shaft disc and a locking nut. The two ends of the rotor are supported on rolling bearings, which are fixed to the casing with bolts.

4、 Hammer breaking machine price

What is the price of a heavy-duty hammer crusher? According to different models and production, the price range of hammer crushers varies. The price of low production hammer crushers ranges from tens of thousands to hundreds of thousands, but the price of high production and high standard heavy hammer crushers is around several million.

The manufacturer of Jinqiang Heavy Hammer Crusher sells it directly from stock, making it more timely to ship. This means that the equipment you buy is much cheaper than intermediaries, and after-sales service will be safer. The specific price of heavy-duty hammer crushers is welcome to inquire online for more information. Our technical manager will answer your questions.

5、 Hammer breaking machine manufacturer

Jinqiang Mining is a large-scale manufacturer of hammer impact crushers, specializing in the production of equipment for heavy hammer impact crushers for over 10 years. With an excellent research and development team, we create high standard and high-quality equipment for heavy hammer impact crushers. The heavy hammer impact crushers produced by the company have a long service life, durability, simple operation, uniform particle size of the finished product, and few overfilling phenomena Advantages such as low energy consumption.

6、 Hammer crusher structure

The structure of heavy hammer crusher manufacturers' equipment mainly consists of a pull rod, front impact frame, rear impact frame, impact lining plate, main shaft, lock block, pressure plate, rotor frame, plate hammer, impact plate, rotor, etc.

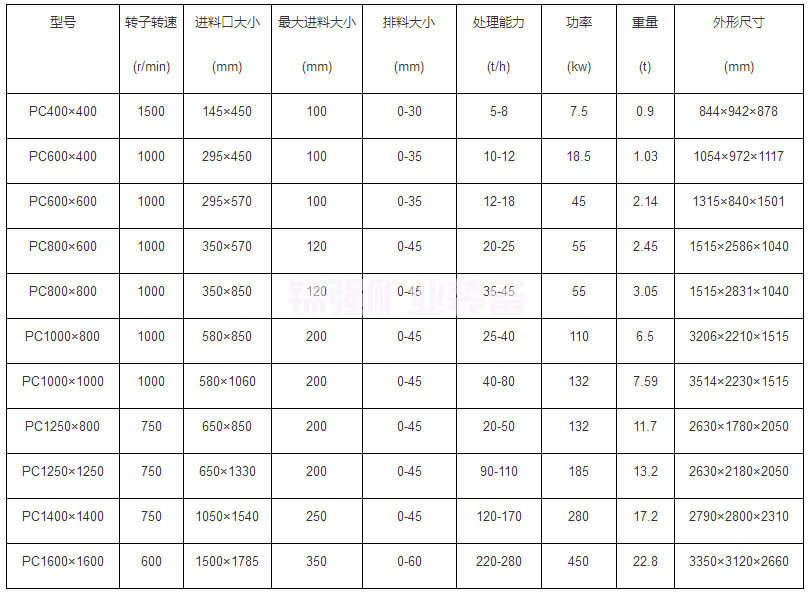

Hammer crusher Technical Parameter:

Hammer crusher Related products