Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > Product Center > Screening equipment > Ore washing machine

24-hour phone/WhatsApp:+8619870423316

24-hour phone/WhatsApp:+8619870423316

Cylindrical ore washing machine equipment image:

Cylindrical ore washing machine equipment details:

Introduction to cylindrical ore washing machine:

Cylindrical ore washing equipment is commonly used for various difficult to wash block iron ores. Large cylindrical ore washing machines are divided into two types: drum type and drum plus screening strip type. The large cylindrical ore washing machine can divide the washed raw materials into+40mm and -40mm secondary commodities, and the -40mm internal double spiral structure trough type sand washing machine can further clean the raw materials into+2mm and -2mm secondary commodities. The ore washing efficiency can reach up to 98%, which is the most effective method for difficult to wash iron ore. The large cylindrical ore washing machine consists of. The cylinder section is composed of a pulping section and a screening section, and the cylinder body is made of wear-resistant rubber as a jaw.

Working principle of large cylindrical ore washing machine:

The cleaning cylinder section is supported by four towing wheels, the electric motor drives the reducer, and the size transmission gear drives the cleaning cylinder section to rotate at low speed. Iron ore with mud and lime powder is fed from the feeding port and enters the rotating drum. It is cleaned by installing a wear-resistant rubber lining plate with a certain angle of view inside the drum, which continuously drives the throwing down. The entire process is moved several times from the feeding end to the feeding end, and is washed and rinsed in both directions or reverse directions. The clean iron ore is lifted by a large Cylindrical ore washing machine and unloaded into two layers of conical screens, which are divided into coarse, medium, and coarse The three fine particle size distributions are discharged respectively. Sewage with sludge is discharged according to the perforated partition at the feeding or feeding end.

Advantages and characteristics of large cylindrical ore washing machines

1. The cylindrical ore washing machine has a large processing capacity and strong ore washing ability;

2.The 2 long shaped ore washing cylinder ensures a long residence time for the material inside, fully and effectively dispersing the material;

3.The cylinder body of the 3-cylinder ore washing machine adopts thickened steel plates;

4.Heavy bearings, gears, and supporting wheels for 4 mining cylinder washing machines;

5 high-power motors and gear systems generate efficient torque;

6. Flush the inner wall of the cylinder with high-pressure flushing water;

7.The maximum feed particle size can reach 230mm.

The website of cylindrical ore washing machines provides information on manufacturers of large cylindrical ore washing machines and cylindrical stone washing machines. To learn more about product information such as quotations and principles of large cylindrical ore washing machine manufacturers, please consult Jinqiang Mining Equipment. The cylindrical ore washing machine manufacturers sell directly at affordable prices. Welcome to purchase.

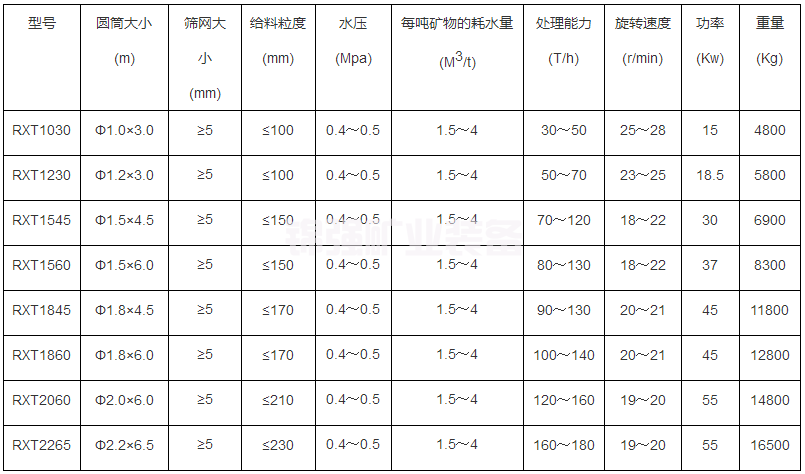

Cylindrical ore washing machine Technical Parameter:

Cylindrical ore washing machine Related products