Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > Product Center > gravity concentration equipment > Jigging Machine

24-hour phone/WhatsApp:+8619870423316

24-hour phone/WhatsApp:+8619870423316

Beneficiation jig equipment image:

Beneficiation jig equipment details:

1、 Working principle:

After the raw ore is sent into the jigging chamber, due to the stirring effect of the diaphragm, the ore particles are layered according to their specific gravity in the medium. Fine and heavy ore particles pass through the gaps and sieve holes of the artificial bed particles and deposit in the storage hopper of the jigging hopper. The upper coarse and light ore particles (materials) are washed towards the discharge port at the end of the sieve by the medium flow. Due to the position of the rear jigging chamber being 50mm lower than the front jigging chamber, the light ore particles overflow through the tail plate of the front chamber and enter the rear chamber, After being jigged again, minerals with different densities are separated to complete the sorting operation. The jig equipment for mineral processing is a new type of modern gravity separation equipment, which has formed a series for promotion and use.

The working principle of the beneficiation jig is a kind of energy-saving gravity separation equipment developed and improved on the basis of the traditional jig according to the theoretical layering law of the jig bed. Its jigging pulse curve is zigzag, making the rising water flow faster than the falling water flow; The rising time is short and the Fall time is long, which overcomes the defect that the rising and falling water flow produced by the sine wave pulsating curve jig is the same with the action time, enhances the looseness of the bed layer, alleviates the suction effect, makes the heavy mineral particles in the minerals fully settle, and greatly improves the enrichment ratio and recovery rate of the equipment.

2、 Application scope:

The beneficiation jig is widely used for separating minerals such as gold, tin, tungsten, titanium, hematite, iron ore, coal, etc., especially in the field of manganese ore beneficiation. The beneficiation jig is one of the modern gravity concentration equipment. Because of its large processing capacity, wide range of beneficiation particle size, and simple operation and maintenance, it is widely used as a rough or clean beneficiation to separate placer gold, tin, titanium, hematite, iron ore, coal and other minerals, especially in the field of manganese ore and Baryte beneficiation. The sand gold jig beneficiation equipment belongs to gravity beneficiation equipment, using water as the beneficiation medium and utilizing the difference in specific gravity between the selected minerals and gangue for separation. The large feed particle size is 6-8mm, but in some cases, the large particle size can reach 12mm. Shajin jig beneficiation equipment is mostly diaphragm type, and the stroke and stroke can be flexibly adjusted according to the specific gravity of the selected mineral. Shajin jig beneficiation equipment is widely used in the gravity separation process of tungsten, tin, placer gold, hematite, brown iron, manganese, titanium, antimony, lead, tantalum, niobium and other metals.

3、 Processing capacity

The jigging equipment for beneficiation uses electromagnetic stepless speed regulation, with uniform agitation, stable ore flow, strong adaptability to wide selected materials, good separation effect for medium and fine particles, and water saving. As the jigging equipment for beneficiation has large processing capacity, wide range of separation particle sizes, and simple operation, the jigging equipment for beneficiation has been widely used for the separation of Baryte, placer gold, tungsten ore, tin ore, Hematite and seashore placer ore. Traditional jigs are mostly driven by circular eccentricity, and their jigging pulsation curves are mostly sinusoidal. Due to the fact that the rising and falling water flow velocities and action times generated by diaphragm movement are basically the same, it is not conducive to the loosening of the jigging bed layer and the stratification of ore particles according to specific gravity, thereby affecting the equipment's sorting ratio and recovery rate.

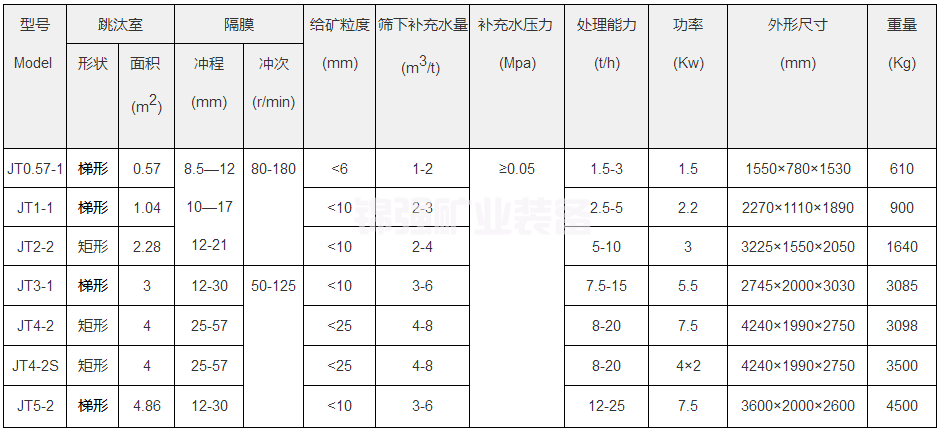

Beneficiation jig Technical Parameter:

Beneficiation jig Related products