Service Phone:

+8619870423316

Service Phone:

+8619870423316

Service Phone:+8619870423316

Service Phone:+8619870423316

current location: home > Product Center > gravity concentration equipment > Chute equipment

24-hour phone/WhatsApp:+8619870423316

24-hour phone/WhatsApp:+8619870423316

Spiral chute equipment image:

Spiral chute equipment details:

1、 Introduction Overview

The spiral chute has high efficiency gravity concentration equipment of China's excellent standard. Shicheng spiral chute beneficiation equipment is used to separate iron, tin, tungsten, tantalum, niobium, gold ore, coal mining, monazite, Rutile, zircon and other metal materials and mining enterprises with sufficient proportion difference from 0.3-0.02mm fine sand. Ganzhou Jinqiang Mining Equipment is the source manufacturer of professional Shicheng spiral chute manufacturers.

2、 Spiral chute Equipment structure and materials

The Shicheng spiral chute beneficiation equipment consists of six parts: a feed homogenizer, a feed chute, a spiral chute, a commodity extraction tank, a commodity gathering hopper, and a trough support frame (including a cross or triangular frame). The spiral groove formed by connecting spiral pieces is a key component. The spiral plate is made of fiberglass anti-corrosion (fiberglass elastomer material) and connected together with anchor bolts. The selection surface of the spiral chute has a wear-resistant layer of prefabricated components. It has the advantages of lightweight, sturdy, and durable daily necessities. The upper side of the spiral chute is equipped with a multi tube feeding homogenizer to evenly distribute the ore, making it easy to operate. The ore separator is randomly placed on the cross (or tripod) of the support table. The evenly divided coal slurry is slowly fed to the surface of the spiral groove by the feeding groove at the head end of the spiral groove for screening. The tail of the Shicheng spiral chute beneficiation equipment is installed in a valve block type new product extraction tank, and the screened new products are divided into three (or four) new products according to grade along the axis. Change the total extraction width of each new product by adjusting the position of the valve block. The new product gathering bucket is a circular tube that gathers and guides the extracted double head ore flow separately. The cross-section of the beneficiation spiral chute and the tangent slope transformation of the curve are particularly suitable for the selection of fine particle raw materials. The Shicheng spiral chute beneficiation equipment has the advantages of simple structure, no fitness sports parts, light weight, low noise, and convenient installation and maintenance. The hardness of metal composite materials commonly used by manufacturers of spiral chutes in Shicheng is 9, second only to bare drills with a hardness of 10.

3、 Application scope

The beneficiation spiral chute is suitable for screening copper ore, Ilmenite, Chromite, Bauxite, zircon, Rutile, monazite, phosgenite, tungsten ore, tin ore, tantalum ore, niobium ore and other rare metals, non-ferrous metals and mining enterprises with different proportions of coarse materials with a particle size distribution of 0.3-0.02mm. The Shicheng spiral chute beneficiation equipment has the advantages of smooth and easy operation throughout the selection process, wide range of allowable changes in ore concentration values, high aggregation ratio, high utilization rate, small land occupation, low water consumption, simple structure, no driving force, large output, simple installation, convenient practical operation, and good investment effect.

4、 Operating methods and principles

Set up the Shicheng spiral chute beneficiation equipment, correct the bisector, fix it in a suitable position with iron frame or wood, send the stone sand to the two feed outlets on the top of the spiral type by the sediment pump, add water for filling, adjust the concentration value of the mineral slurry, the mineral slurry will certainly swirl from high to low, and create an inertial Centripetal force in the rotating slope water flow, According to the force of vortex flow and the effect of Centripetal force, the ore and sand are separated, the titanium concentrate is injected into the titanium concentrate bucket and connected in series with pipelines, the industrial waste slag flows to the industrial waste slag bucket and receives the sand pool with pipelines, and then is discharged by the sediment pump. The Shicheng spiral chute concentrator completes the whole process of the concentrator.

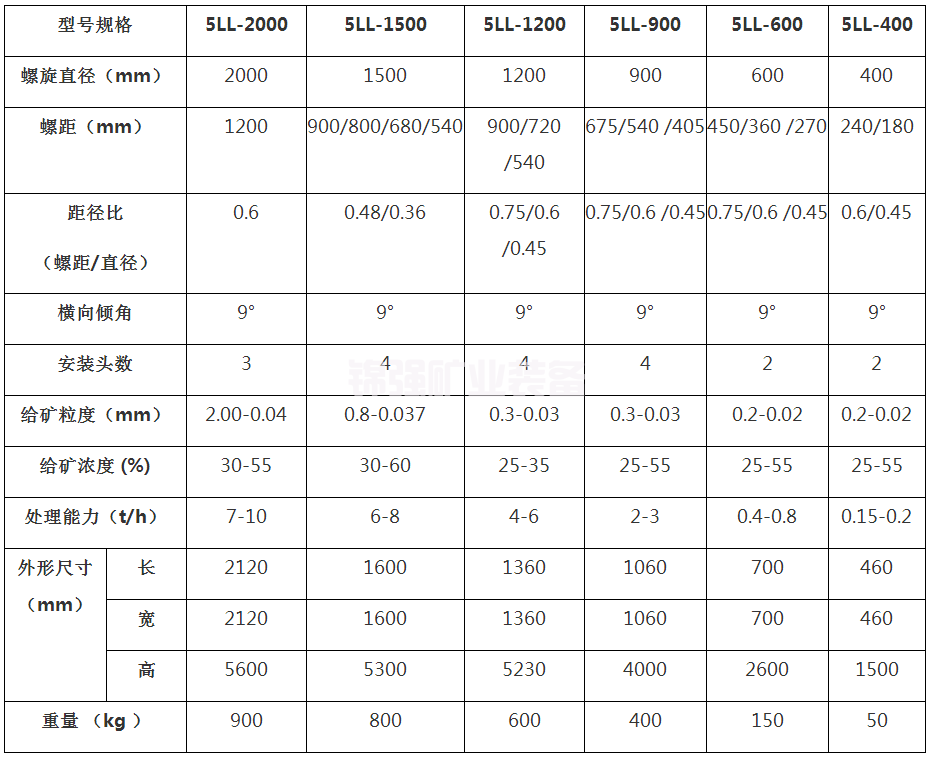

Spiral chute Technical Parameter:

Spiral chute Related products